Can I say before I get going, the following relates to my experiences with domestic machines. Industrial machines are slightly different beasts, but much of the following applies to them too.

The development of the sewing machine reflects that of engineering in general – often someone comes up with a great new big idea. That idea is then gradually refined over time. The great ideas are either brought in quickly across the market – through licensing of patents for example, or more slowly, as patents expire.

The fundamental elements of the lockstitch sewing machine machine were developed in a relatively short space of time in the late 1840’s and haven’t changed. Subsequent developments up until the 1980’s mostly refined those relatively few original ideas to produce machines that sew better, faster and are simpler, lighter and cheaper to make. That refinement process led to a series of design types – which whilst they differ in detail, are the same in concept.

The digital revolution starting in the 1980’s allowed a new big idea to come in, with needle position controlled by electronics instead of mechanically. The design refinements of that idea are still progressing.

Design Elements

The fundamental design options in sewing machine design are:

1 Bobbin type.

One of the original great idea with lockstitch machines was use a shuttle containing a “long bobbin”. To form the stitch on a long bobbin machine, the whole bobbin within its shuttle passes through the loop in the upper thread. Long bobbin machines are of two main types – oscillating shuttle, where the shuttle moves back and forth in a straight line and vibrating shuttle, where the shuttle moves around an arc. An alternative early great idea, which has now become the standard, is to use round bobbins, with a mechanism that cleverly allows the thread to pass around the bobbin whilst it rotates, but whilst the bobbin remains fixed in position.

2 Hook type

The type of hook used is a major factor in the design of any round bobbin machine. The hook allows the lower thread to pass through a loop in the upper thread to form the stitch and is found in nearly every machine manufactured after WW2. Hooks can be rotary or oscillating and mounted horizontally or vertically. Vertical hooks can be either side facing or front facing. The hook type has a big influence on the overall design of the machine. Over time the move has been towards horizontal, rotary hook machines which are able to run at high speed and are easy to load bobbins, but other designs persist.

3 Bed type

Lockstitch machines are generally either:

Flat bed – where the work surface is level with the needle plate and best for large flat pieces of work.

Free arm – where the work can pass around and under the needle plate – useful for sleeves and trousers.

The type of bed will influence the hook type – free arm machines being more suited to vertical hooks in order to simplify the mechanism in the free arm and allowing it to be made smaller.

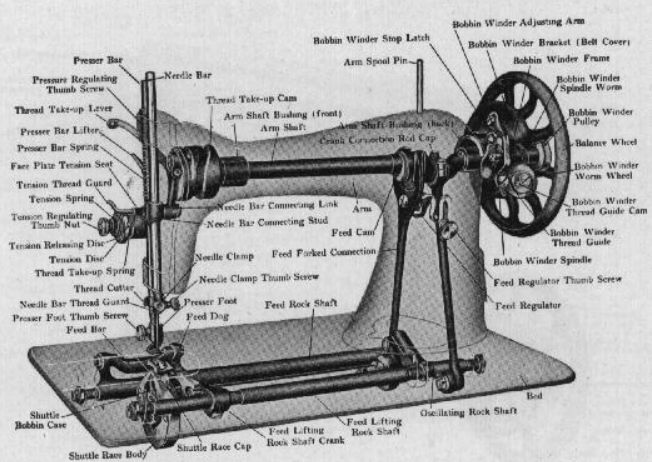

4 The feed

The fabric needs to be moved in a very controlled way in order to produce a nice looking stitch. Since the very early days, a design using a moving toothed plate or “feed dog”, below the bed, used in conjunction with a spring loaded “presser foot” pressing down on the fabric and fed dogs from above has been standard on virtually every sewing machine produced. It’s a design concept that obviously works! Refinements mainly involve having the presser foot able to move in conjunction with the feed dogs to have better control of thick or difficult fabrics and / or two sets of feed dogs to allow fabric to be stretched or gathered as it is sewn.

5 The needle drive.

Virtually all sewing machines work in conjunction with an upper shaft that drives a needlebar up and down, performing one stitch per revolution. In most cases it’s the upper shaft that’s driven, with power for the rest of the mechanism being taken in various ways from that shaft.

6 The feed / hook / shuttle Drive

Driving the mechanical parts of a sewing machine needs a further mechanism and a number of types of drive have been developed. The most frequently encountered types are as below. The name I’ve given them is just to help categorise them. I’m not aware of each type being categorised, so the references to Singer machines is mainly that more Singers have been made than other manufacturers. Many of the ideas were developed by others and just used on Singer machines. It’s interesting (to me at least) that the same hook / shuttle drive mechanism can be used by more than one type of machine. For example the Singer 12 is an oscillating shuttle, but the same drive type operates a front facing oscillating hook in Bernina machines.

Design Types

Lots of machines fall into categories or design types, with each type using the same options for the design elements within each type. Some of these types, using the name of a machine that typifies that type is as follows:

1 “Singer 12”. Uses a bevel gear drive take-off from the upper shaft, through a vertical shaft to a horizontal crank and connecting rod driving the shuttle. Also used in much more refined form on Bernina oscillating hook machines from the 1950’s onwards as well as machines such as the Singer 328 of the mid 60‘s.

Singer 12. Oscillating shuttle.

2 “Singer 15”. This uses a cranked portion of the upper shaft to drive an oscillating lower shaft that operates feed length and also, via a sliding block, the hook drive, Feed up/down is via an eccentric on the upper shaft. This is a highly robust system. Used on classic Necchi machines and vast numbers of far eastern made machines of the post WW2 period through to the seventies, apparently largely due to the gifting of the Singer 15 design to the Japanese (and possibly Italians?) at the end of WW2. Hard to mess up the timing!

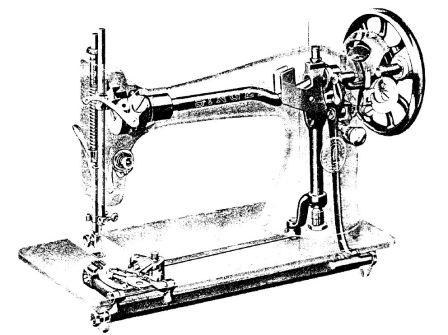

Singer 15. End facing vertical oscillating hook

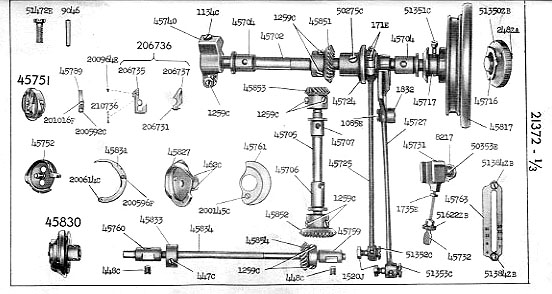

3 “Singer 27” – uses a clever cranked upper shaft arrangement to transfer an oscillating drive through a vertical shaft through to a horizontal bar that operates the oscillating hook or vibrating shuttle. Used on lots of horizontal bobbin machines. Simple, elegant system. Used on Singer 27,28,66, 99.

Singer 28. Vibrating Shutttle

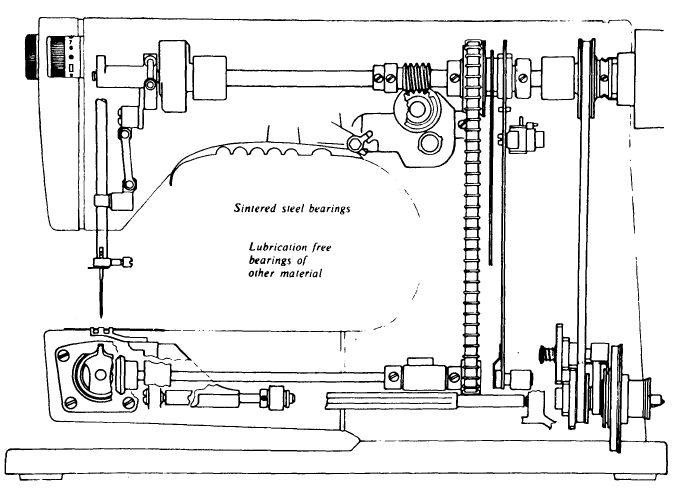

4 “Pfaff”. Uses a toothed timing belt to transfer power from the upper shaft to a lower shaft, sometimes with bevel gears on the other end of the lower shaft to turn the rotary hook drive through 90 degrees. First incorporated into the Pfaff 130 in 1932, the system was used later under license on the Singer 206/306/319 machines. Very similar systems are used on the Husqvarna machines from the ‘50’s through to the early ‘80’s. Also used on Lada sewing machines. An elegant, lightweight system, but relies on the integrity of the drive belt, which can deteriorate over time or through wear. Easy to mess up the timing!

Husqvarna 5/6000 series. Side facing vertical hook, “Pfaff” hook drive.

5 “Singer 201”. Similar to 1 above. Uses a bevel gear drive take-off from the upper shaft, through a vertical shaft and through two more sets of bevel gears to a lower shaft and then to drive the hook. First used by Singer in the ‘30’s on the 201; subsequently used on rotary hook Singer models and very many others – Brother etc. from the 1960’s onwards, initially using all steel gears and latterly plastic. Precise and adaptable to vertical or horizontal rotary hooks. Can suffer with backlash issues and other wear related issues with the bevel gears. The most widely used system on modern machines.

Singer Featherweight – End facing rotary hook

6 “White VS” . The upper mechanism is very similar to the Singer 27, but the shuttle sits on a long arm below the machine, hinged in the middle. According to Elena Emblen – and she’s usually correct – also used by New Home, Jones in the UK with its CS models and a few German manufacturers. The momentum of the swinging arm acts to increase the effective needle piercing power, allowing these machines to “punch above their weight”.

![1Shot_20180916_161045[1]](https://danhopgood.files.wordpress.com/2018/08/1shot_20180916_1610451.jpg?w=723)

Above: Underbed mechanism of a 1900 Jones’ Family CS machine.

I find it interesting to see the development over time of the basic ideas. Maybe if you’ve read this far, you do too!

Great overview, Dan! I had not realised that Singer 15 had a different crank inside than 27/66. As to whether it’s hard to mess up the timing – it depends! Cheap machines are usually extremely easy to mess up, but not at the crank but near the bobbin assembly, especially in forward-facing designs of any type. 😛 Old Singer 15 and 66 had timing locked with pins instead of screws, the same in my Haid & Neu and in Necchi Supernova. But they were all pre-1960. Not sure about later models, but all Japanese post-WWII machines that I’ve fixed had “loose” timing (set with screws, not pins), and boy was it easy to mess up!

Another note on hook type: horizontal hooks are only used in domestic machines because it is considered easier to insert the bobbin (although a lot of people disagree). I have never seen an industrial machine with a drop-in bobbin – they are usually vertical rotaries, but there is a type for extra heavy duty work that is in fact a vibrating shuttle, but vibrating vertically. Not an antique machine – very much modern. I think it’s for millinery or some such – tight corners and very thick material. Can’t find it now! Should have bookmarked it… 😐

LikeLike

Found it! It’s a sort of a trivial vibrating shuttle with an extremely short arm. But the point is that the bobbin case moves – that’s the important bit. In round bobbin machines the bobbin case is stationary. So this one is for making shoes and it has a bullet type bobbin case with long bobbins: https://www.google.co.uk/amp/s/m.aliexpress.com/item/32580618932.html?source=images#ampf=undefined

LikeLike

Thanks for enlightening us all again Elena. I’ve certainly not seen anything like that before. Side mounted vertical vibrating shuttle is how I’d describe that when I first saw it, but there’s a hook as well. In my description above I’m saying it’s one or the other – which it obviously ain’t always!

LikeLike

I think there are lots of hybrids around! The hook here is not important though, I believe. You know like in a regular TS or VS, the bobbin case is also the hook because it picks up the loop with its sharp “nose”. The cradle is then just to hold the bobbin case. But here because of the extremely short arm (non-existent arm, perhaps?), the bobbin case would have to have a funny looking curved beek – and it does, but it is now a part of the cradle.

LikeLike

A note on feed. Many industrial machines have dual feed (an integral walking foot) and quite a few have needle feed (upper feed only). Industrial dual feed is very different from Pfaff’s IDT or domestic walking foot attachments.

LikeLike

Elena,

Thanks for all that. I realised when I was writing this that there were lots of opportunities for saying things that aren’t correct. I forgot about needle feed machines and aren’t familiar with them – so I stand corrected on that.

I like vertical hooks – especially when using a table mounted machine (as industrials invariably are) where access is possible from underneath. Access can be a pain on free arm machines using an extension table though – e.g Lada / Bernina machines, but then now having my collection of machines, I can just use those as free-arms and the problem goes away.

LikeLike

Agreed! No one in industry uses free arm machines with extension tables! 🙂

I think your overview mainly applies to domestic machines – perhaps it would be an idea to say so in the beginning? Because phrases like “the majority of lockstitch machines” apply to industrials as well, and they are often very different. 🙂 I am not criticising what you wrote – I think it is interesting and I learned new things, so thank you! 🙂

Regarding needle feed – they are fun! Old Davis machines from USA, or here in the UK the little chain stitcher called “Ideal”, and of course the Tailor Bird (TS). Apparently not that great, but people always say such things about the competition, don’t they.

LikeLike

Comment now made at the start about industrials!

Dan

LikeLike