Bill Holman, retired sewing machine dealer and host of several Groups.io sites including “Vintage Singers”, is not a great fan of the Singer 328. He posted his personal opinion of it along with similar machines in a document included in the group files there.

I quote “If you compare a 328/327/329 or a Stylist with the ‘average’ sewing machine, they don’t come out all that bad. But I was working for Singer when they came out, and comparing them with machines like the 201/301/401, and using these as a basis of comparison, they stunk.”

He then referred to 3 issues he has with them:

1. Not being able to adjust the needle distance from the hook.

2. Being noisy.

3. Having a weak motor.

Bill has mended more sewing machines than I’ve had hot dinners and given me support in my novice interest in these machines and I respect his views greatly, so he must be right, right?

An alternative, rosier view of the Singer 328 has been given by others, including Elena of Elena’s vintage sewing machine blog

Elena documents a 328 as one of her “crew” of regularly used machines. She also has vastly more experience with sewing machines than me and whose opinion I also respect greatly. If a 328 is good enough for her to use regularly, it must have a lot going for it.

They can’t both be right, can they?

By a strange coincidence a 328 came up on Gumtree round the corner from me, so I bought it, for a fiver, out of curiosity to see what this machine is like for myself.

The photo and description of the machine I bought were pretty awful, being described as a “vintage Singer sewing machine for refurbishment”, with a partial picture of the back of the machine. The only thing that got my interest was that the picture showed two positions for spool pins on the lid (one had been broken off) – which means it was double needle capable. Further research of google images showed it was probably a 328. The machine was partly covered in a film of dried up oil, but hey – that’s a good thing for long term storage.

I picked the machine up and it was pretty obvious it hadn’t been used in a long time. The power plug was one that fits into a light bulb socket. I thought that idea went out in the ‘30’s!

The machine itself was complete and in good health, although almost seized from its oil having dried out. The motor drive belt and rubber feet had perished and needed replacement. It had also lost all its accessories. Cosmetically it was not bad – a few scratches here and there. It had the likeable aura of a regularly used and looked after machine in its youth, whose owner just got too busy looking after grandchildren to bother with sewing, so the machine just sat in its cupboard. That thought was backed up by the seller’s tale of it being her grandma’s.

Above: a bit more cleaning needed!

The foot pedal was weird. The rubber power lead grommet had come adrift, so there were single wires showing. The rubber feet were seemingly missing, but when I opened the pedal up, the feet were inside the case. The suppression capacitor made in 1964 was still there and looking healthy, reinforcing my belief that the machine hadn’t been used for a long time. The pedal mechanism was very sloppy and out of adjustment. I concluded that someone had taken it apart, fiddled with it, given up and screwed it back together with the feet loose inside. I binned the suppressor, adjusted the pedal mechanism and gave it a clean and it all now works great.

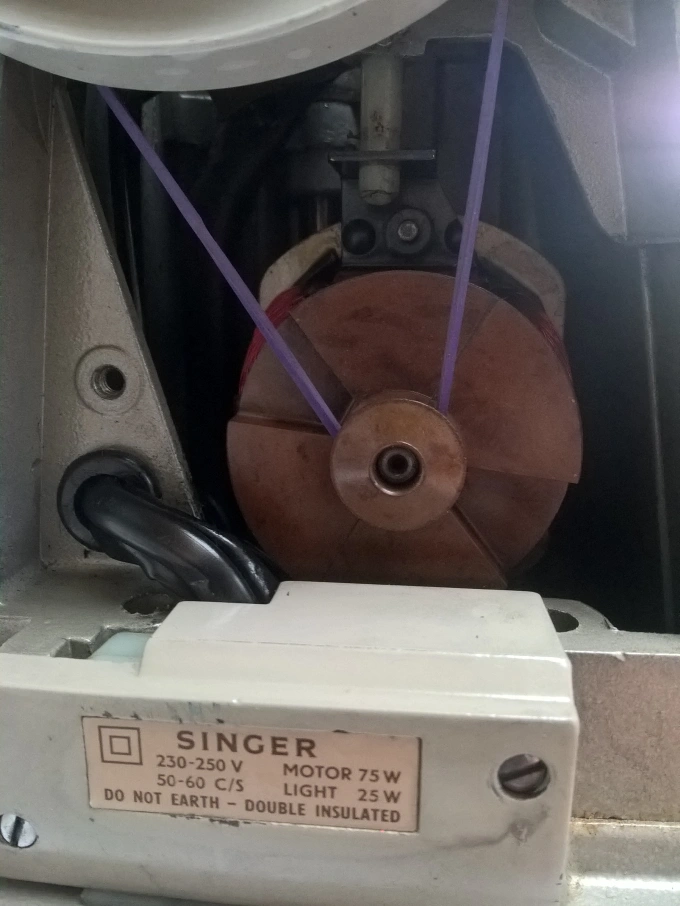

I took the motor out and cleaned the commutator, which I did with the brushes still attached, since everything looked pretty healthy. The fact that it’s an open motor helps – as the parts are all easy to get to. The motor was easy to remove too. There was a slight issue that there’s a plastic fan on the end of the motor, held on with a threaded bar that screws into a thread on the shaft of the motor. The bar was a loose fit on the plastic, but moving the position of the bar resolved the issue. I put a bit of thread lock on the bar to keep it in position. I’ve since found out that the bar screws out the other side of the shaft until it locks the Bakelite pulley in place. All a little bit delicate for my liking. Break the pulley and it will be an issue getting a replacement.

Above: I’ve now put on a proper drivebelt!

The case was all blotchy and the vinyl looked really dirty and faded. However, after a drop of Cif, a nylon scouring pad, some elbow grease and a bit of Armorall vinyl cleaner it looked almost new.

The usual technique of surgical spirit worked a treat to clean the old oil off the machine, both the body and the moving joints. I used cotton wool pads for large areas and cotton buds for the fiddly bits.

My previous blog about the 1963 Which? Report listed the Singer 401, new, at a whopping £115.00 whereas the 328 was a mere £73 10 shillings. Lots of corners need to be cut in order to get a machine with similar features 40% cheaper surely?

The main differences between the 328 and 401 where savings have been made are as follows:

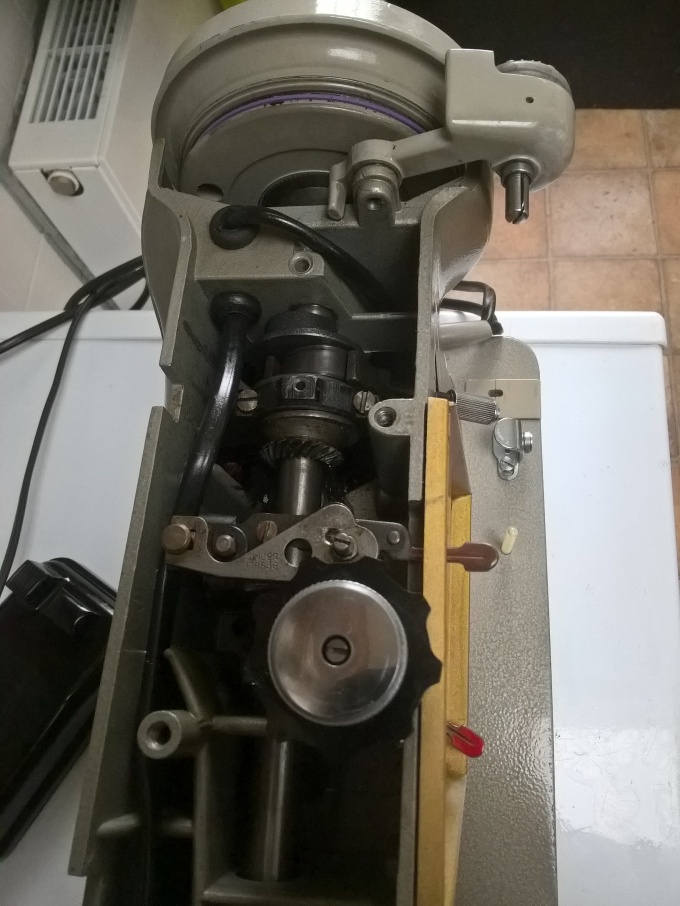

- The oscillating hook of the 328, uses lots of parts common to other, earlier Singer machines. Machine specific parts, like the hook pitman, are simple and therefore cheaper to make. The 400 series have a rotary hook and all bevel gear drive – which is more complex to produce.

- The 400 series machines use a gear driven, cased motor. The 328 has belt drive and an open motor.

- Maximum Zig zag width is 4mm on the 328, 5mm on the 401.

- Maximum stitch length is 6 ½ stitches per inch on 328, 401 is 6 stitches per inch

- 401 is slant needle, making it more difficult to produce. 328 is low shank, so visibility to the work is less, but much easier to find accessories to fit on the 328.

- Arguably punching power is improved on the 328, from the oscillating hook drive generating more torque, plus a vertical needle and lower gearing. Evidenced by the ability in the Which? magazine test of a 328 sewing 7 layers of canvas, a 401 only able to sew 3 layers.

- Max sewing speed of 401 (1300spm) is faster than the 328 (1100 spm), probably the result of the smoother running mechanism.

- The 401 has a needle plate that rises up on moving a lever for darning; you have to change the plate on the 328

- Cams are one at a time and plastic on the 328 – they’re mostly steel and built in on the 401 (although setting the right cam on the 401 is not intuitive)

- Power lead and foot pedal are permanently fitted to the 328. 401 has plug and socket on the machine

- Light fitting is crude on the 328. 401 has a lens and looks better

- 401 has a plastic base – not sure if the 328 had one – mine doesn’t have a base.

- 401 has had money spent on improving the aesthetics

- Cheaper paint finish on some 328’s – on mine it’s a kind of “hammerite” for the bulk of the machine– textured, but hard wearing, with conventional paint on the top and faceplate.

Lots of these changes had a big effect on the way the machines were constructed, but the dilution of features available to the user on the 328 are not that great. Loss of top speed and rougher running is not a huge issue – especially for the less experienced / occasional users a cheaper machine would attract.

There appear to be at least two cosmetically different versions of the 328, each available in at least two colours – beige and khaki green. On Elena’s webpage, her machine is shown having a buff, smooth finish with a circular moulding on the cam cover and two separate plates on the front. My machine has a green khaki hammerite finish. There is a single plate on the front of the machine. There’s a light switch, which looks crude but is an original feature as I’ve seen it in pictures of other machines. My machine was made in May 1964 according to the serial number. Maybe the altered paint finish and single plate on the front of the machine were an effort to save production costs? I think all 328’s were made between February ’61 and ’65, which is not a long production run. it was followed by the 338, which had very similar mechanicals, but looked more modern and came in softer colours – like light blue.

The 328 was made both in Kilbowie, Scotland as the 328k and in Canada. I’ve seen a photo of a 328 with the label “Made in Canada from components made in Great Britain and Canada”. I think both factories produced models for the US market – with 110 Volt motors. Bill expressed a gripe with a lack of power with the 328, but my machine and other 240V 328k’s don’t seem to suffer from this issue. Some 110V users in the USA don’t seem to have an issue either. It seems likely to me that some 328’s with 110V motors had a different, lower power motor, which is what the machines Bill experienced had.

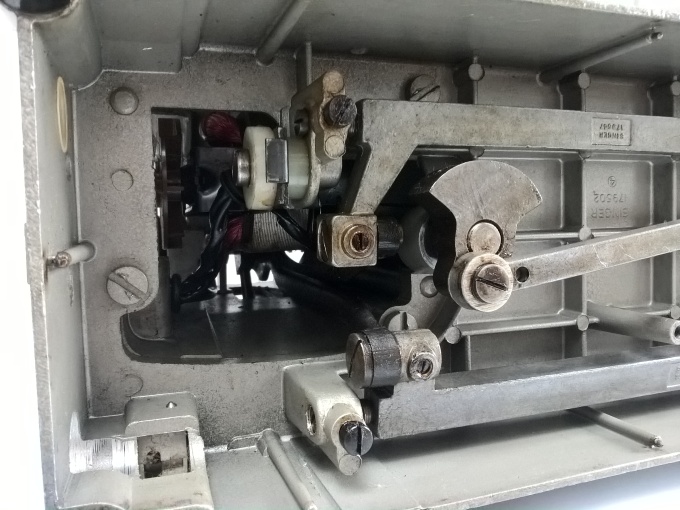

I got a service manual for the machine, which shows the 328 to be easy to work on. What did surprise me was that the manual contains, on page 29, instructions for how to vary the distance between the needle and the hook point. Bill’s main gripe with the machine was this couldn’t be done. I think the restriction on moving the needle as Bill describes is restricted to the “Stylist” models. (Edit: see update below)

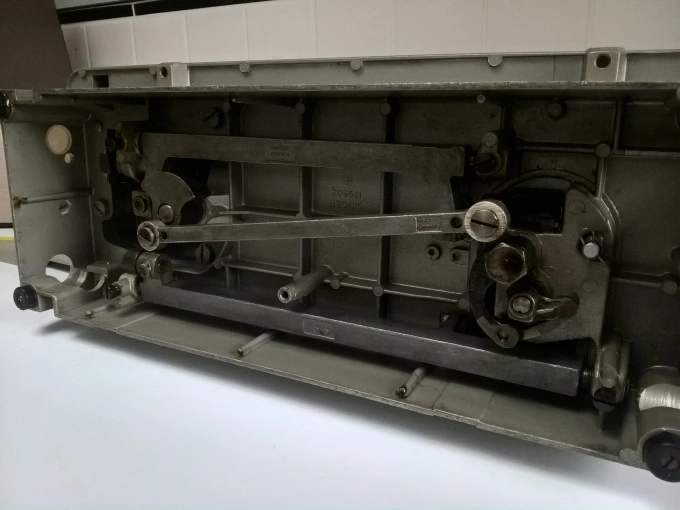

Bill’s last gripe about the 328 was about the machine being noisy. Being a lot like the Singer 66, the machine is an oscillating hooker. The clearance around the bobbin case on the 328 is adjustable, so excessive noise around the hook can be adjusted out. The main drive mechanism joints aren’t adjustable on the 328 like older machines like the 66, so on a very high mileage machine, slop in those joints might be an issue. But for most machines used and maintained properly I don’t see that as a source of noise. Certainly my machine has been used in its 50 plus year life and there’s little play. Comparing it to a 411/401 it’s not as smooth, certainly and it’s harsh at high speed. Keep the speed down though and it sounds quite pleasant! The only other source of noise is the motor and belt drive. My machine, and those of others with 240V 328k’s don’t seem to report motor noise as an issue. Maybe again this is a problem for certain, US market 110 V machines.

I conclude that Bill’s gripes are largely genuine but apply only to some of the US market machines.

I’m sure Bill is correct in stating the 328 was marketed as a cheaper alternative to the 401 series and that salesmen of the time were told to steer customers towards the more expensive models. The 328 certainly had design compromises to get the costs down, which resulted in a lower specification. However, my experience of restoring and using the 328 is that – for UK spec machines at least, a very good job was made of keeping all the most valuable elements of this kind of machine, whilst costing nearly 40% less than the 401.

These retained features include:

• excellent tension control top and bottom

• very fine adjustment capability for stitch length

• interchangeable cams with all the utility stitches you would want

• Singer “old school” quality, bringing with it durability, reliability and ease of maintenance

• double needle capability

• Selectable needle position left/centre/right

I think these retained features, plus the good sewing performance as demonstrated by the 1963 Which? Report are why this machine scored so highly compared with the 401 at the time.

There’s also one feature of the 328 that some of the 400 series machines don’t have — and that’s the ability for treadle operation. I’ve had a go and all you need to do is swap the handwheel for a heavier and higher geared one – a spoked wheel off a 66/99/201 will do nicely – and unscrew and remove the plastic block in the bed. Replace the drive belt with a treadle belt and voila! – a fancy stitch treadle machine. It’s much easier to convert than something like a 411 – I have another post on doing that. You can’t use the bobbin winder with the smaller drive diameter of the spoked handwheel, but resourceful sewists like those reading this far could find away around that…..

Having now restored and used the 328 I like the fact that it’s easy to use, has lots of useful features and no features you don’t want that just get in the way. It has the easy and cheap to run combination of 66 bobbins, standard needles and low shank feet. I’m not a fan of the looks though, it’s almost got almost a military look about it. Rugged, not pretty.

Comparing it to my 411g on the upside, it’s easier to use, a bit lighter and uses standard low shank feet and attachments. On the downside, it doesn’t do chain stitch, I don’t like the looks and it’s not as smooth.

The 328 is more a “date with your significant other of 20 years” than a first date – efficient, comfortable, predictable ….I’d better stop there! I like it and for lots of jobs, because of its usability it would be the quickest way of getting a good job done. That’s a sign of a good machine, surely?

Maybe more of the reason behind why salesmen were told to steer people towards the 401 etc. and away from the 328 was not that the 328 was a bad machine, but simply that the profit margin on sales of the 401 was much better than the 328?!

Dan H

Update 8th Nov ’17

Top tip – don’t play with sewing machines when you’re getting over the flu.

The picture above is the presser bar clamp out of the 328 after I had the machine running at full speed and moved from straight stitch to full zig zag with a 110 needle and a straight stitch needle plate fitted. Big bang, lots of bits of needle flying about and then no presser foot pressure. The impact obviously cracked the presser bar clamp. Helen Howes came to my rescue again with a replacement part. I notice that part she supplied, probably off an old 66, was forged steel and nearly twice as deep as this 1964 sintered steel part. Quality of manufacture was obviously already reducing by that time….

I’m struggling to get a drive belt to fit – reference the post on belts. I’m currently using a toothed belt installed inside out, which works and the drive is much quieter than it was, but is not ideal. Original spec belt is on order, which should be better.

I’ve now adjusted the machine – there was lateral slop in some of the feed joints, which I’ve now eliminated. There was some lateral movement on the eccentric feed too. I took the feed dogs off and sharpened them up with a needle file.

I checked the needle to hook clearance – which is more than the two thou specified maximum distance, but as the machine works I’m leaving as-is for now. I queried with Bill Holman about his statement you can’t adjust the hook to needle clearance. His response was that whilst you can adjust the clearance, the clearance to the needle plate is adjusted at the same time, which could well mean you can’t adjust the hook clearance without causing clearance problems for the needle in the needle plate. On 400 Class machines there are separate adjustments.

I’ve got this 328 working as best it can be, but there is still quite a bit of noise and vibration at high speed. I think it’ll have to stay that way. I’m nicknaming this machine “the tractor” – it’s green, not so good looking and a bit rustic, but easy going and hard working.

Update 14th November

I managed to make a heavy carrying bag with this machine, using a pattern from Tammi at Archaic Arcane. I made life difficult by quilting what was some pretty heavy cotton. At the worst case I was trying to sew through 12 thicknesses of cotton plus at least 4 of batting, which neither the needle or machine liked at all. I well and truly blunted a needle, which I’ve not done before. The machine started making nasty noises under that load, so I think the needle was not under proper control and rubbing on things it shouldn’t which is what blunted it. The inside out drive belt worked flawlessly though. Unfortunately the alternative original spec belt I ordered is too narrow and just slips. Atelier Needlecraft also couldn’t get an industrial belt to fit either. My choices now are rubber belt (yuk), turning the handwheel on a lathe or staying as I am with the inside out belt.

I’m warming to this machine. With a new LED bulb, sewing at moderate speed on sensible fabrics it’s nice – certainly sews a nice straight stitch. Zig zag seems to need more top tension, which is OK once you’re used to it.

Update 21st November

I posted a note on the Vintage Singers site about my finding that you could adjust the hook to needle clearance on the 328. Bill Holman responded along the lines that whilst the adjustment can be made, the needle consequently moves in the needle plate, such that you could have the needle to hook clearance right, but the needle position in the needle plate may be wrong and there’s nothing you can do about it. On the 400/500 series machines there are separate adjustments.

Still no luck with getting a belt to fit. The inside out one is constantly trying to roll itself over, so rides up out of the handwheel pulley, putting too much tension on the belt. I’ve got a shorter belt on order and plan to turn down the handwheel on a lathe to get the pulley narrower.

Update 26th November

STILL trying to get a belt to fit. Ordered one that was too long – then ordered another supposedly 10mm shorter that arrived the same length. Grr! Yet another on order, 15mm shorter. (further update, that one’s too short!) For now I’ve reverted to a rubber stretch belt, which does work, although puts more tension on the motor than I’d like.

I wondered if I could make the machine any quieter. Comparing it to my 411’s/401 it really was a bit of a clunker. I went through the adjustments in the service manual describing how to adjust the driveshafts. Both the top shaft, cam stack and vertical shaft were a bit loose. Adjusting these has made quite a big reduction in noise and vibration. It’s still not in the same league as the 411/401, but I’ve removed its “tractor” label.

I also had a go at trying to widen the zig-zag width, but concluded there’s no adjustment for this. (further update: see new post on this subject!)

Update 20 January ’18

I ended up buying another 328 since I’ve agreed to let someone else have the first one. The “new” one came with a nice case, a load of feet including a low shank special purpose foot, 7 cams and a steel bed extension that fits nicely in the case. All for the princely sum of £9.26. Was dirty, the driest machine I’ve come across and the power cords were more twisted than fusili pasta, but it was hardly used. Was sold as “not working”. The only problem I could find was that because the machine had been tipped upside down, the bobbin case had moved out of position and caused a lock up. I just took the bobbin case out, cleaned and oiled everything and we’re ready to rock…..

This machine is slightly different from the other. Whilst at first glance they look the same, the second one, made in early 1964, has a metal motor cover attached with two screws, whereas the newer machine has a plastic cover attached with a spring catch and one screw. The older machine also has no switch for the light – it’s just on all the time the machine is plugged in, which suits me fine.

Update 1st March ’18

Finally, I’ve found a drive belt solution that works as it should for these 328’s.

It’s a 400mm long vee belt that’s custom cut to width based on a fixed number of ribbs. Photo above shows a 4 rib wide belt. Details here:

With this particular belt, each rib is 2.34mm wide. I ordered 3 ribs wide, equating to a total width of 7mm. This width fits the handwheel nicely – the belt sits on the shoulders of the slot, not the bottom – and it also fits in the pulley wheel on the motor in the same way. The belt is a tad too long, but as it fits so nicely, you get no slip despite the belt being a bit loose. That’s as it should be – the belt should only be tightened to the point it doesn’t slip, then a higher proportion of the power of the motor gets to drive the machine. The belts are really good quality – and very cheap. Result!

Update 3rd Jan 2019

Mike in the comments asked about how to remove the tension assembly. Answer is there’s a set screw accessible fromthe front of the machine as shown in the following extract from the service manual:

The set screw is hidden quite well behind the zig zag mechanism, so a short, thin screwdriver is needed to reach it. The service manual itself can be downloaded by joining the Vintage Singers group at Groups.io:

I read your post with much interest, Dan, thank you! 🙂 Where did you get the service manual, please? I want one too. 🙂

My 328K looks different, as you noted – it is one of the first made, 1963. I think they quickly changed the look to your variant, and it came also as straight stitch only as well as plain zig-zag without cams (with different model numbers but the same look, although different colours). My machine also came with case, and I think yours was supposed to have one as well – it is exactly the same as on 401G series: the lid clips directly onto the base, so you’re not missing a base – it’s supposed to be like that. The lid also houses the removable extension leaf, a box of accessories and the manual. Some of these machines also came with tables, or may be tables were sold separately, I don’t know. That’s why they’ve got hinge sockets.

I’ve installed a Sew-Tric socket on mine instead of the hard-wired cables. Oh, the pedal was working fine but I personally don’t like that pedal design with a little button – my toes are not agile enough, in particular when wearing shoes. 😉

LikeLike

Elena,

Thanks for your comments. I’m a bit confused about the base. My 411 has a plastic base that screws onto the cast aluminium base of the machine. the outside of the plastic ends up flush with the bed of the machine, so when you put the lid over the top, the lid sits nicely. The lid still clips directly to the machine. Without the plastic base the lid flops about a bit.

I did think about having a plug and socket for the cables, but decided I’m going to keep this original, partly as I don’t want to spend much on it.

I’m planning to order a plastic spool pin, drive belt, a set of needle plates, a couple of feet and some cams from Helen Howes. I get on OK with the Singer button controllers – don’t know why…

LikeLiked by 1 person

It looks like there were different cases out there. My 431G didn’t have any plastic base and the lid clipped onto the metal base descending all the way to the ground. Exactly the same as with my 328K. It wouldn’t be possible to put the lid on if there was a base.

LikeLike

As for the Singer pedals, some people love it, some hate it – just a matter of taste. 🙂

LikeLike

About the spool pins: they are removable, by design. You can’t get the lid on otherwise, so they come out quite easily. You can find replacements on eBay quite cheaply, but use plastic ones, like the originals – steel ones don’t fit very well.

I like this machine because it just works. 🙂 No fiddling, insert a cam and go. Also makes manual buttonholes like I described before. Yes, you cannot raise the needle plate like on 401G, that’s a minus. But this is also not possible on free arm models like 431G.

Compared to other twin needle machines, the 328 (and the 401) takes either a twin needle or two separate needles, so you could match the needle to the type of thread you are using.

LikeLike

Elena,

I can get the lid on mine OK with the one remaining spool pin on the machine. I’ll have to make sure the extra one I get doesn’t stick up more than the existing one then!

I don’t see swapping the needle plate for a darning one is much of a handicap, but a proper drop feed has to be better for darning or free motion as it produces a completely level bed.

I do like the option of using two needles – that feature is on my 411. The option of different needle sizes s good, plus the cost of replacing needles is a lot less.

LikeLike

It’s not just needle sizes but needle types. For example, one top stitch, the other metallic for a bold design with golden shading. 🙂

LikeLike

I have inherited a Singer Style-O-Matic 328 and am teaching myself to sew using it. Everything was going fine until yesterday when the machine began to merely hum when I stepped on the foot control. I can turn the machine by hand , and it makes good stitches, so I’m wondering if it only needs cleaning or some lubrication. Can you steer me to a website where I could find help troubleshooting this machine? Also, what’s the difference between the 328 and the 328K?

LikeLike

Ed,

Sounds like the machine either has some thread jammed in it and / or is dirty and needs a good clean. Oiling is something that should be done regularly once you know it’s clean. Have you got a user manual? You should be able to find a free version online. That should help re. cleaning out the dirt. If you look at some of my other posts you’ll see I use a technique of opening up the machine and using surgical spirit / rubbing alcohol on the end of a cotton but /qtip on all the moving joints to get rid of old oil, before using a good sewing machine oil to lubricate it. Doing that is likely to make a big improvement.

The letter on the end of the model name is the factory where the machine was made. So 328k is Kilbowie (Scotland).

Dan H

LikeLike

Dan;

Thanks!

The machine has been idle for a long time, plus there’s been recent dusty remodeling going on nearby. I’ll try a bit of rubbing alcohol & q-tip cleaning, and then oiling to see what happens. I do have a user manual, and it does indicate several points to lubricate as well as some NOT to lubricate.

This machine has no ON/OFF switch for the work light. Does that indicate anything about its age?

LikeLike

Ed,

No on off switch means it’s an earlier build. Does the machine look the same as mine? Really early ones have different, better looking badges. There should be a serial number under the machine. Do a search on “date Singer sewing machine”and type the number in and you should get a date of manufacture.

LikeLike

I am following up with some comments regarding my inherited 328. After considerable disassembly, cleaning, and reassembly (with no parts left over) followed by liberal oiling at the spots indicated in my owner’s manual and lubrication of gears, also as shown in manual, the machine ran a little better, well enough to sew a bit, but still sluggish and not at the top speed I remember. Any suggestion?

LikeLike

Yes, my 328 machine looks almost identical to yours

LikeLike

Ed,

There’s too much friction in the mechanisms somewhere. How tight is the drivebelt? It should be only just tight enough not to slip. You should be able to move the belt up and down 1/2″ or so.

Dan H

LikeLike

Hi there. Just bought a 328k and there’s a problem with the foot pedal. There was a wire loose on the connector close to the machine. Single grey wire coming out of internal workings. I reattached with a second grey wire bit when I plugged it in the machine just started on its own. I tried attaching with the yellow and black wires and now the light works but nothing else. Any ideas?

Also, I’m a bit heavy footed on that little button. Can I replace with a full foot pedal? And I so, what do you recommend?

Absolute newcomer to sewing so please forgive if my terminology isn’t up to scratch

LikeLike

Jon,

Difficult to say what the solution is without seeing the machine. You bypassed the speed controller to get full power all the time. Then you managed to get two lives or two neutrals to the motor. Can you find a wiring diagram and trace the wires? You can change to a full width pedal by just connecting the two wires from the old controller, but your problem is inside the machine and you need to solve that problem first.

Regards,

Dan H

LikeLike

Jon,

Wiring diagram for your 328:

Click to access 3pin.pdf

Good luck!

Dan H

LikeLiked by 1 person

Thanks for this this Dan. I’ve just taken the plunge and purchased a 328k, but in taking the tension assembly off (to clean it) I broke the tension stud. I’ve been sitting, looking at the machine for two days. My question is, to release and replace the stud (on which the tension assembly is mounted) do I need to take out the needle bar, to get to the stud’s release screw? There’s an unnerving silence on the internet about this, making me suspect the answer is yes.

LikeLike

Michael,

No you don’t need to take the tension assembly off to remove the tension stud. There’s a set screw accessible inside the machine. Post updated to show you where……

Regards

Dan H

LikeLiked by 1 person

Thanks Dan, I bought an unusually long thing screw driver to get at it. Done. Love your blog.

LikeLike

It’s been a while since I looked at this post Dan, so I’m glad you mentioned it in the Vintage Singers forum. My 328 also came without a light switch but I added a toggle switch to the power cord as I do like to have an on/off switch handy. It has been put aside for the past couple years as it was having some tension issues and I had too many other machines clawing at my leg, but I think that will be easily remedied when I just make time on the bench for it. It also may not be the quietest machine I’ve come across, but is certainly within the realm of ‘normal’ as far as noise goes. There is some opinion that it is not very good for free motion work, and my brief attempt bore that opinion out! I did have a lot of ‘catching’ while moving the fabric but wonder if it’s because the tension was off.

LikeLike

I recently inherited a 328k. Unfortunately the light is burned out. Any idea where I can purchase a replacement?

LikeLike

Sandra,

I’m not sure where you are. What you’re after is a bulb with a spec the same as this :https://www.amazon.co.uk/dp/B01MZAFZ9Q/ref=pe_3187911_189395841_TE_dp_1

BA15D bayonet bulb – 110V in the USA, 230/240V in europe. Some bulbs are quite long and sometimes don’t fit for that reason – you want a short one. Another issue with some bulbs is they have a large flange where the glass part meets the metal part and then it won’t push in far enough. Look for one with a small flange.

Good luck!

Dan H

LikeLike

Hello Dan.

I picked up Singer 328 on a curbside this “spring” and wanted to use it as utility machine. It was missing pedal and power cable but I have hooked it up temporarily with benchtop power supply and made it run.

I cleaned and lubricated it and machine rotates fairly smoothly.

Unfortunately I cannot make it stitch – it is tearing spool (upper) thread, despite that fact i loosen tensioner to some very low value – 1 or 2.

Can you suggest, please , what to look at , ma be adjust? Thanks a lot.

LikeLike

Gennady,

This could be several things. I’ll try and contact you direct about this.

Regards,

Dan H

LikeLike

Hi Dan!

Over the years I’ve worked on all of the “good” Singer sewing machines with the exception of the #101 and #115 machines. They’re all good but some have some idiosyncrasies that have to be understood to get great performance. The #328k certainly has it’s share of “you better check that out close!” as well.

I have a 328k that in my opinion sews just as good as the 403A I have. The biggest problems the 328k tends to exhibit are worn out upper and lower tension springs, and the factory setting of the needle bar height that is WAY too low. After replacing both springs, I reset my needle bar height to where the needle eye is about 1/16th of an inch below the hook. It was previously set about 1/4 of an inch below the hook, and this particular machine had been barely used since its birth in Dec. 1962, leading me to believe that was the factory setting.

The 328k in my opinion is a good sewing machine, and that bit of noise it has is no more disconcerting than that of say, a Singer #66 (#66s sure are very finicky!).

Best Wishes,

Dave

LikeLike

Dave,

Thanks for your comments. I suppose there’s no way of checking whether that needle bar height came out of the factory like that. I suppose that could have slipped through quality control at the factory. I haven’t tried to swap underbed parts between a 328 and a 66, but the basic hook mechanisms are very similar, so It’s no surprise they sound similar. I have seen worn lower tension springs on machines, but not upper tension. Has the upper tension spring been abused soemhow I wonder?

Comparing the 328 and 400 series machines, I find I get more reliable zig zag out of the 328 without changing top tension setitngs. Then again though, the max zig zag width on the 328 is less.

LikeLike

Dan,

My 328k had sat around for years, barely used, with all of the attachments and a half-full bottle of factory oil still in the accessories box; original manual, plus the baby maternity ward I.D. bracelet of the lady’s son dated Dec. 1963. It took kerosene and a few days of oil soakings to free it up, lol!

I think the 328k is a wonderful machine, as is its distant ancestor, the #66. My one machine I will never sell is a rather unusual #66. It is a Goodrich Mercury Model 66 copy made in the late ’40s to early 50’s. It has some unusual features such as the stitch length adjuster and the bobbin winder unlike any other I’ve ever seen. All wrapped up in an unmarked machine with a brown crinkle paint finish, I’ve never even seen a picture of another one, and I had to do all kinds of things to turn it into a champion performer. Working on just about any older Singer is always fun in the unexpected.

Cheers,

Dave

LikeLike

Hi Dan, my 328k lay unused for years. I got it out and made some masks. All was fine then suddenly it started to sew on its own. Then the needle stopped moving but the engine kept running. Now the engine runs if it is plugged in. The drive band doesn’t seem to be going round – but there is a smell of rubber. Any ideas?

LikeLike

I have a 328k, mom bought for me in high school, 1963. It has literary sewn to the moon and back several times I’m sure. Unlike my vacuum cleaner my sewing machine has bee used EVERY DAY. From high school home ec, wedding, baby cloths and layette, children’s cloths, family cloths home decor and now quilts….. but would like to know is the bobbin case suppose to be loose or it is suppose to be in the machine nice and tight. Mine is loose. thank you … c in mt

LikeLike

Cleone,

Wow, that’s quite an advert for the durability of the 328!

Regarding the bobbin case, yes it should be loose – but only slightly loose. There needs to be enough space around the bobbin case for the thread to pass easily between the case and what it sits in. If the thread doesn’t pass freely then it won’t sew a nice stitch. Too loose and the machine makes more noise than it should. If the machine isn’t overly rattly I’d just leave it alone and keep sewing!

Best wishes, Dan H

LikeLike

thanks,,, you have a great web page here. I will be checking in from time to time and and thank you for the advice… machine is sewing well, i keep it clean, oiled and lubricated…

LikeLike

i do break a lot of belts….. could the tension be to tight???? i noticed a link where someone was having belt issues…. thx

LikeLike

Cleone,

The issue I had with the drivebelt on the 328 is I couldn’t find one wide enough to fit properly. A narrow belt needs loads of tension to avoid slip. You shouldn’t need much tension on the belt. Are you using a rubber belt or a bee belt?

Regards,

Dan H

LikeLike

hi Dan… don’t know what kind of belt, I usually buy singer brand belts, have a stash on hand so when it breaks I can continue on sewing. It seems to fit well, the belt is round and not a flat belt. I hate to go messing around with the machine when I’m not sure what I’m doing, sometimes that can make things worse.

LikeLike

I have one of these Singer sewing machines. recently tuned up in great condition. free to a good home in GA.

LikeLike

I’m in GA as well and trying to find a replacement drive belt. Would you happen to know the part number and where I could buy one?

LikeLike

Hi, do you still have the Singer 328 machine?

LikeLike

Carol,

US machines may be slightly different to UK spec machines, so what fits my machine may not fit yours.

The official belt for UK models is this: Simanco #193077 (15-/8″ – 39.5cm O.D). That was too narrow for my machine though and it always slipped – although I was using used belts, which may have already been worn. The one I use now is a j section industrial drive belt, 3 ribs wide, 400mm (15 3/4″) Outside diameter.

Good luck with your search.

Regards

Dan Hopgood

LikeLiked by 1 person

Excellent Blog Danhopgood! I have been spending my morning reading, THANK YOU! I picked up a 328K from Shopgoodwill a couple of years ago. It came with instruction manual, all cams, tons of feet, and vintage needles. I am 100% with you on it looking tractor-like. I live in farm country and that is the first thing that came to my mind upon seeing it.

It needed a good cleaning and oiling but ran great out of the gate. I had terrible trouble with skipped stitches that would only be remedied by switching over to a vintage needle. I have some things to investigate on that from Elena on her vintage sewing machine blog.

My reason for writing here is in regard to the reputation this machine has, as you referenced. I have not found anything other than the needle thing that is a major turn off. Yes, you have to switch cams, but that takes all of five seconds. I am impressed with the quality of the straight stitch. I am a major vintage Viking/Husqvarna lover, and have found them to be more powerful and quiet than the 328. But…..Even my beloved Automatic 21’s don’t have the quality of straight stitch that my 328 has. It is perfection.

Thank you again for the great blog–it is much appreciated

LikeLike

Many thanks for those kind words Appleton!

Dan H

LikeLiked by 1 person

Hello Dan,

I enjoy reading your interesting and informative blogs; they are such a useful guide to all things Singer VSM. I took your advice and found the service manual for 328’s at vintagesingers@groups.io. Excellent bed-time reading!

I have a set of gray Singer 328J triplets (I’m in Canada, where the J’s breed in the wild), one slightly older without light switch, and the other two with light switches. They are identically filthy and mucky inside and out, and I am trying to clean one up to sell it. I would like to remove the cam stack assembly so I can access the gobs of old oil, grease, cobwebs, animal hairs and threads that have congealed under all those parts, but I have come to an impasse.

The manual states on pg 37 that I am to first loosen the set screw Z2, and then remove the cam stack screw stud (Y3). Firstly, the set screw is seized (working on that with penetrating oil), but secondly, on all three machines, there is no screw stud, only a stud. I can see it through the hole below the cam stack, but there is no slot in which to insert a screwdriver. I thought perhaps it was just covered in so much oil that the slot was full, but I have cleaned it to silver shininess and there is still no slot. All three machines are like this.

I just watched an Andy Tube video in which he removes this screw stud, which has a slot, but he’s working on a 327K, not a 328J, so that is no help. I could send you a picture of a shiny slot-less stud in an access hole but that’s all it looks like.

Have you encountered this? Any ideas how I might get that assembly out?

Thanks so much again for your generosity in writing these wonderful posts. You are an excellent teacher!

Best regards.

LikeLiked by 1 person

Veez,

Thanks for your kind words. I haven’t yet needed to take the cam stack out of a 328, although I haven’t had experience of machines as mucky as the ones you’re working with. I think my advice since the machines are different to the serrvice manual would be to play it safe and remove everything apart from the cam stack to get as much space as you can. If that’s not enough space to get everything clean I’d be tempted to do either the old Singer Service technique of submerging the whole machine in parafin (they used “Varsol” – but parafin would do the same thing) for a few days to clean it- or the technique used by Andy of Andy Tube – with water based “Crud Cutter” and a hose down with water afterwards.

LikeLiked by 1 person

Thank you Dan! I will continue with my search. I have a great resource group here in Canada as well (Archaic/Arcane), and J machines are certainly more common here.

One other question though: What do you mean by Parafin/Paraffin? It is a generic term for about eight different chemicals! I think you are referring to Kerosene, correct?

Best regards.

Veez Beez

LikeLike

Hi Dan,

thank you for an excellent post providing loads of information on these old machines; much appreciated.

Very helpful when trying to maintain the Singer 328P machine I inherited from mum, which in some ways I’ve been using since before I was born 😉

Best wishes,

Jady Mulqueeney

Australia

LikeLiked by 1 person

Thank you Dan for your excellent post. I wanted to tell you there are three 328 versions, you mentioned 328K from Kilbowie and 328j from Canada but there is also 328P from Penrith, NSW Australia. I have had this machine for a few years and because I have so many machines I don’t use it. Twice now I have thought I would sell it but when I get it out to take photos I do a trial sew with it and fall in love with it all over again! It looks like it has saved its place, yet again!

LikeLike

Thanks for educating us further!

All the best, Dan H

LikeLike

So glad I found this! I have an old 328 that I love. There’s a number on the embossed metal plate that says 13608M. it was made in Britain and I bought it back in the mid 80’s in Lincoln, Nebraska… USA. It has worked like a dream even though I haven’t played much with features… just some basic sewing and quilting. Today, all of a sudden, it started SCREAMING at me while stitching. And even pressing the pedal all the way down, it would go slow. I tested the bobbin winder and that goes at full speed so must be something inside. EMBARASSED to say that I have never cleaned or oiled it, as I wasn’t that serious of a sewer… and obviously somewhat stupid. Have just cleaned it, per the manual, and am picking up some oil and lubricant hoping that fixes it. Thanks for the great info and pics… !!

LikeLike

Morgan,

Sounds like a slipping drive belt to me. Hope you get the machine sorted.

Regards

Dan H

LikeLiked by 1 person

What a fine article, thank you for taking the time to share your experience and expertise. I have a 329 which is the straight stitch version of the 328. It was frozen and needed some TLC when I got it, but the effort was really worth it. My 329 is a great machine. Solid as a rock.

This series of Singer machines do not get the attention they deserve. Fine machines.

LikeLike

Thanks for the fine article. Someone contacted me about a free 328 and I am researching it to see if it is worth bringing into the herd. My favorites are a bevy of 301s, some 15s, a 401 and some 99s. I love the detail and explanations here. Thanks!

LikeLike

Hi Dan, Can I ask how you went on long term with the belt that you bought that you thought suitable? I have just obtained one of these machines and I need a new belt for it, also one for my 317 which is supposed to take the same size belt. I ordered a belt off ebay, but that doesn’t fit. Your input would be gratefully received.

LikeLike

Kerry,

The belt replacement I bought is working fine – the machine in question went to one of my wife’s neices and they are getting on fine with the machine….

LikeLike

Many thanks for your speedy response Dan. It is much appreciated. Best regards, Kerry

LikeLike

I have the Gray 328K.Made In Canada. I have had excellent luck using the Singer 160506 Buttonholer on the machine. I use the 328 Lifting Plate first and lay the General Purpose Plate OVER that. Machine set at straight Stitch.center Needle position. If this has been posted before,my apologies.

LikeLike

Have recently acquired a 328P and have been using Fashion Disc #3 Blind stitch. Do you know of a way to have the notch land to the right rather than left?

LikeLike

Emman,

The only thing I can think of is to reverse the fabric as it feeds through the machine. I appreciate that might not be practical…

LikeLike